Master Your Blade Repair Operations

Windventory is the complete inventory management solution for blade repair teams. Track field inventory, manage teams, and get real-time alerts when inventory runs low.

Complete Inventory Control

Transform your wind blade repair operations

Built specifically for blade repair professionals, our platform eliminates inventory chaos caused by manual "Excel tracking", and keeps your teams productive in the field.

Field Inventory Tracking

Monitor all your vehicles and field teams in real-time. Know exactly where your resources are and how they are being used.

Smart Inventory Alerts

Receive instant notifications when inventory runs low. Never run out of critical consumables or equipment again.

Proven Cost Savings

You can save 30.000 € per season through accurate tracking, elimination of waste and delayed ordering.

Built for the Field

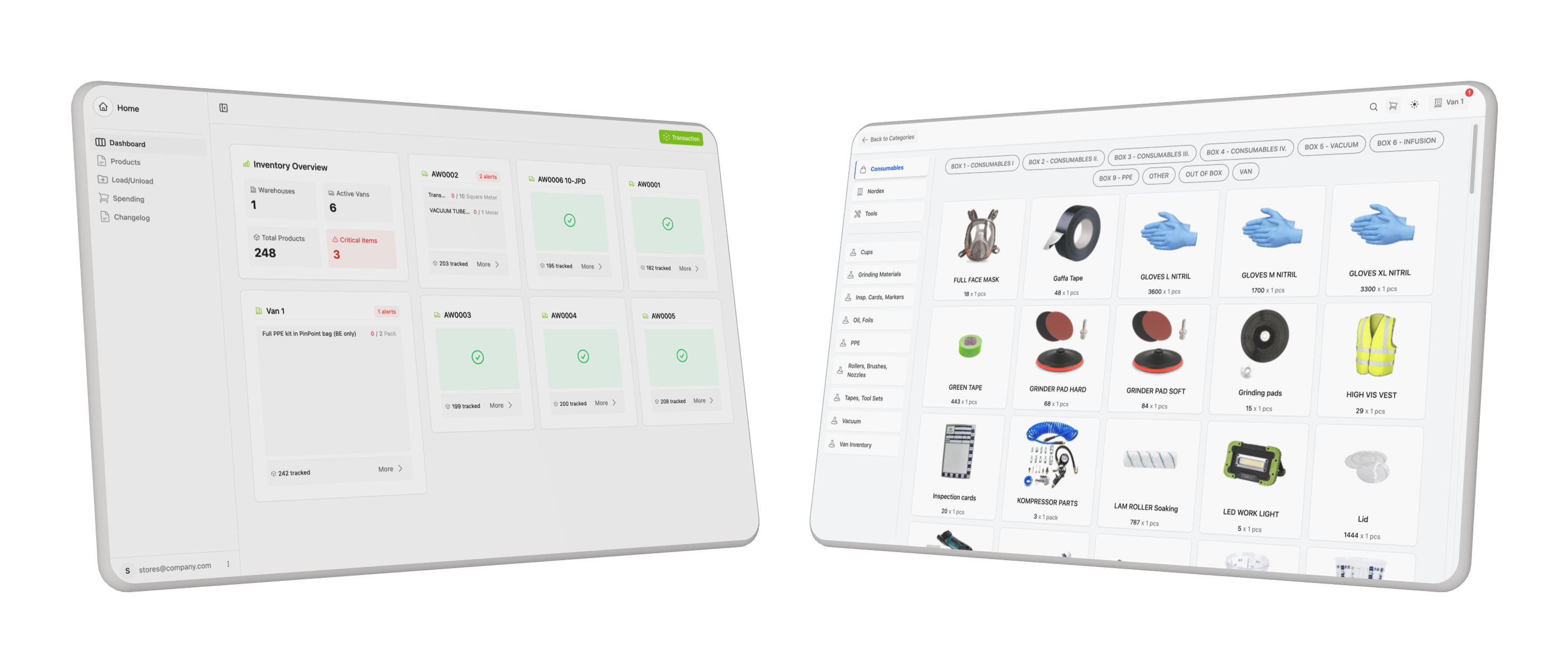

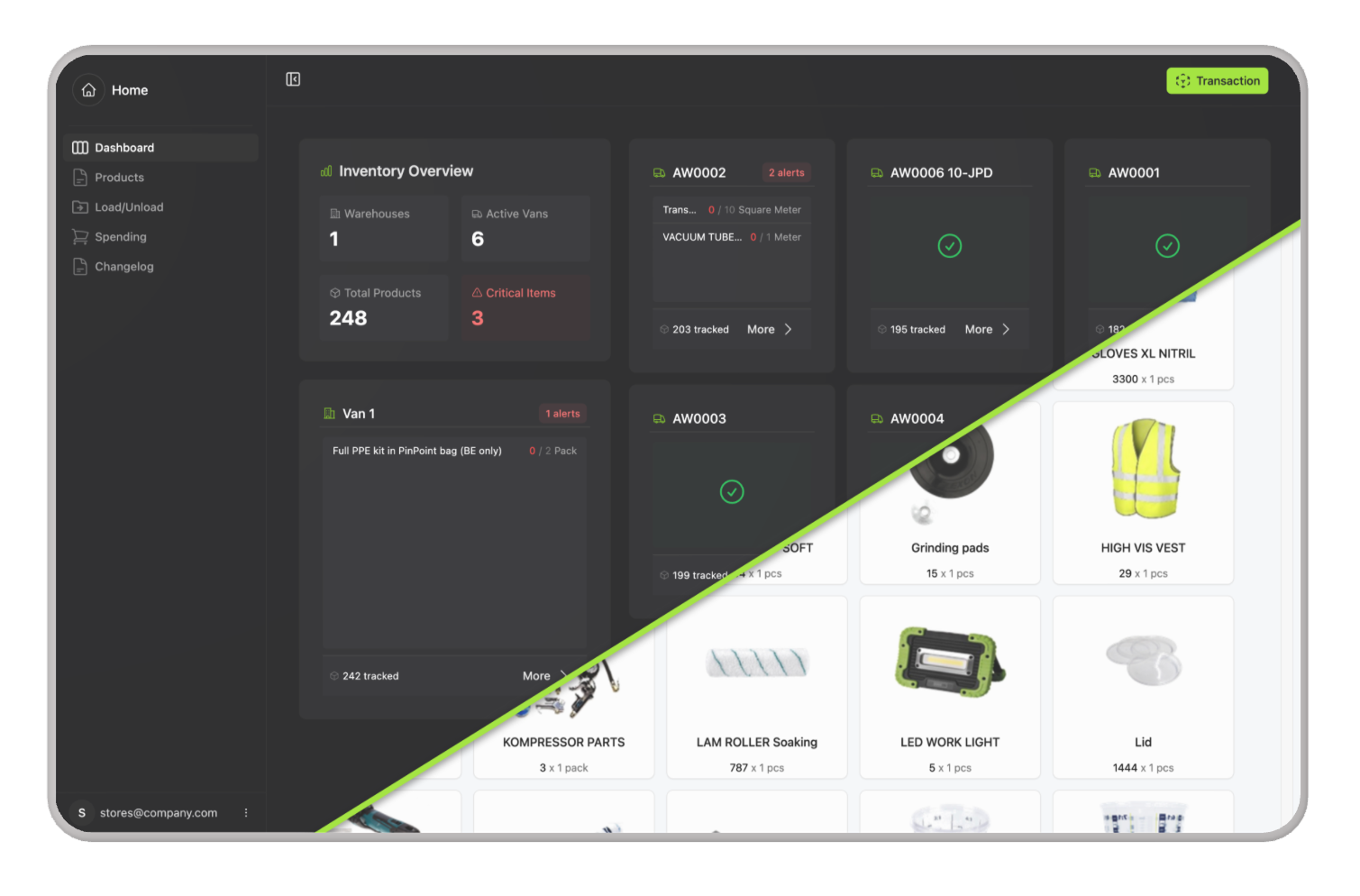

Two powerful views for your entire operation

Whether you're managing the warehouse or working on turbines, Windventory adapts to your needs with intuitive interfaces designed for real-world conditions.

Warehouse View

Complete oversight for store managers. Monitor stock levels, plan transfers, and manage your entire inventory from one central dashboard.

On-Site Field View

Streamlined interface for field teams using tablets in vans. Super easy to click through, even with gloves on.

Powerful Features for Wind Professionals

Every feature designed to cut repair turnaround time

From organized consumables to real-time tracking, each feature solves real problems faced by blade repair teams every day.

Smart Organization System

Box & Category structure with thresholds and units organizes consumables exactly as technicians see them. Faster reporting, fewer picking errors.

Lightning-Fast Search

Global search & multi-filter locates any product in 2 clicks, even on a tablet. Minimizes time spent on searching for products so technicians stay on-task out on turbines.

Template-Based Transfers

Pre-plan common van restocks or job kits with bulk transfer templates. Guarantees the right resin/abrasive mix heads out every time.

Spending Mode

Technicians can "tap-out" items as they use them with live quantity & units. Real-time consumption capture keeps inventory counts trustworthy.

Offline Ready

Works seamlessly offshore or in low-signal areas. Local storage prevents data loss even when connectivity is poor.

Complete Audit Trail

All transaction history log with time-stamped & traceable adjustments. Clean chain of custody for ISO 9001 compliance audits.

Manual Override Controls

Supervisors can reconcile physical counts fast with logged manual quantity overrides. Shrinks write-off windows, freeing capital tied in ghost stock.

Role-Based Access

Admins gatekeep edits while technicians self-serve essentials. Protects master data while empowering field staff, lowering admin overhead.

Security Hardening

No user-side password changes removes social-engineering vectors. Helps pass client IT security reviews required by major wind-farm operators.

Success Stories

Trusted by Wind Energy Professionals

See how Windventory is transforming blade repair operations across Europe and beyond.

"Windventory saved us 30.000€ in the first year alone. The accurate inventory tracking eliminated waste and our technicians never run out of critical materials anymore."

"The tablet interface works perfectly in our vans, even with safety gloves on. Our techs love how easy it is to track consumables without paperwork."

"The offline capability is a game-changer for offshore wind farms. Even when we lose signal in the nacelle, we never lose our inventory data."

Transform Your Blade Repair Operations Today

Join the wind energy professionals who've already cut costs and improved efficiency with Windventory.